China 6 Axis 1800mm Arm ya kai atomatik Karfe MIG Welding Robotic Arm

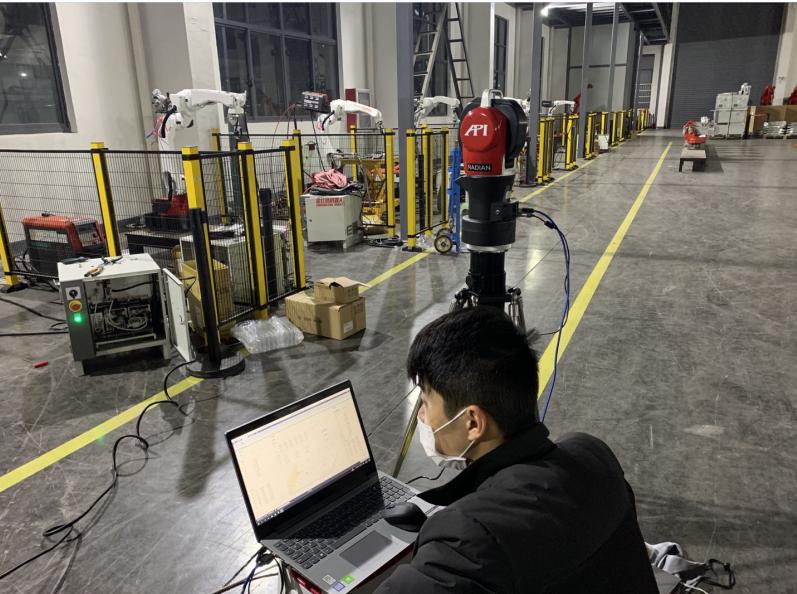

GWAJIN LASER CALIBRATION INGANTACCEN MATSAYI

JHY yana amfani da hanyar daidaita laser don gwada maimaita daidaiton matsayi na mutum-mutumi.Bayan gwaje-gwaje da yawa, daidaiton matsayi na robot ɗinmu maimaitu ya fi ± 0.08mm.

AMFANI DA MANYAN SALAMAN DOMIN KAYAN HAKA

Robot core na'urorin haɗi irin su servo motor, RV reducer, harmonic reducer, servo drive da sauransu duk suna amfani da manyan samfuran China, waɗanda aka gwada ta hanyar amfani da dogon lokaci don tabbatar da cewa sun dace da robot ɗinmu.

SAUKI MAI KYAUTA

Kulawa yana da sauƙi, bisa ga jagorar kulawa da mu abokan ciniki da kansu ke iya aiki cikin sauƙi.

BAYAN GARANTI SALLA

Kowane abokin ciniki yana da ƙungiyar sabis na bayan-tallace-tallace.Idan kuna buƙatar kowane taimako bayan-tallace-tallace, Pls tambaya a kowane lokaci.Ƙwararrun injiniyoyinmu za su warware shi a cikin mafi kankanin lokaci.Maganar ita ce duk kyauta ne.

| Welding sigogi tunani for m karfe da low gami karfe | |||||||||

| nau'in | farantin karfe | Diamita na waya | tushen gibin | walda halin yanzu | waldi irin ƙarfin lantarki | saurin waldi | Tuntuɓi tip-workpiece nisa | Gudun iskar gas | kusurwar walda |

| Tushen walda mai siffar T | 1.0 | 0.8 | 2.5 zuwa 3 | 70 zuwa 80 | 17 zuwa 18 | 8 zuwa 10 | 10 | 10 zuwa 15 | 45° |

| 1.2 | 1.0 | 3 zuwa 3.5 | 85 zuwa 90 | 18 zuwa 19 | 8 zuwa 10 | 10 | 10 zuwa 15 | 45° | |

| 1.6 | 1.0,1.2 | 3 zuwa 3.5 | 100 ~ 110 | 18 zuwa 19.5 | 8 zuwa 10 | 10 | 10 zuwa 15 | 45° | |

| 2.0 | 1.0,1.2 | 3 zuwa 3.5 | 115 zuwa 125 | 19.5 zuwa 20 | 8 zuwa 10 | 10 | 10 zuwa 15 | 45° | |

| 2.3 | 1.0,1.2 | 3 zuwa 3.5 | 130 ~ 140 | 19.5 zuwa 21 | 8 zuwa 10 | 10 | 10 zuwa 15 | 45° | |

| 3.2 | 1.0,1.2 | 3.5 zuwa 4 | 150 ~ 170 | 21 zuwa 22 | 7.5 zuwa 8 | 15 | 15 zuwa 20 | 45° | |

| 4.5 | 1.0,1.2 | 4.5 zuwa 5 | 180 zuwa 220 | 21 zuwa 23 | 6.5 zuwa 7.5 | 15 | 15 zuwa 20 | 45° | |

| 1.2 | 5 zuwa 5.5 | 200 ~ 250 | 24 zuwa 26 | 6.5 zuwa 8 | 10 zuwa 15 | 10 zuwa 20 | 45° | ||

| 6 | 1.2 | 5 zuwa 5.5 | 230 zuwa 260 | 25 zuwa 27 | 6.5 zuwa 7.5 | 20 | 15 zuwa 20 | 45° | |

| 6 | 220 ~ 250 | 25 zuwa 27 | 5.5 zuwa 7.5 | 13 zuwa 18 | 10 zuwa 20 | 45° | |||

| 4 zuwa 4.5 | 270 ~ 300 | 28 zuwa 31 | 10 zuwa 11.5 | 13 zuwa 18 | 10 zuwa 20 | 45° | |||

| 8,9 | 1.2,1.6 | 6 zuwa 7 | 270 zuwa 380 | 29 zuwa 35 | 6.5 zuwa 7.5 | 25 | 20 zuwa 25 | 50° | |

| 8 | 1.2 | 5 zuwa 6 | 270 ~ 300 | 28 zuwa 31 | 9 zuwa 10 | 13 zuwa 18 | 10 zuwa 20 | 45° | |

| 1.2 | 7 zuwa 8 | 260 ~ 300 | 26 zuwa 32 | 4 zuwa 5.5 | 15 zuwa 20 | 10 zuwa 20 | 50° | ||

| 1.6 | 6.5 zuwa 7 | 300 ~ 330 | 30 zuwa 34 | 5 zuwa 5.5 | 15 zuwa 20 | 10 zuwa 20 | 50° | ||

| 12 | 1.2,1.6 | 7 zuwa 8 | 270 zuwa 380 | 27 zuwa 35 | 4.5 zuwa 6.5 | 20 zuwa 25 | 20 zuwa 25 | 50° | |

| 1.2 | 7 zuwa 8 | 260 ~ 300 | 26 zuwa 32 | 4 zuwa 5.5 | 15 zuwa 20 | 10 zuwa 20 | 50° | ||

| 1.6 | 6.5 zuwa 7 | 300 ~ 330 | 30 zuwa 34 | 5 zuwa 6 | 15 zuwa 20 | 10 zuwa 20 | 50° | ||

Lura:

1. MIG walda yana amfani ne da iskar gas, wanda akasari ake amfani da shi wajen walda alluminium da alawoyinsa, tagulla da alawoyinsa, titanium da sauran kayan sa, da kuma bakin karfe da karfe mai jure zafi.Mag waldi da CO2 gas kariya waldi suna yafi amfani da waldi carbon karfe da low gami high ƙarfi karfe.

2. Abubuwan da ke sama don tunani ne kawai, kuma yana da kyau a sami mafi kyawun tsarin walda ta hanyar tabbatarwa na gwaji.Diamitocin waya na sama sun dogara ne akan ainihin samfura.